Mine Detection Drone

|  |  |  |

|---|

Our Purpose

This project aims to make the process of detecting and neutralizing mines in military operations safer and more efficient. Mines pose serious threats to civilian and military lives, and detecting them through traditional methods can be difficult, dangerous, and time-consuming. Therefore, with the mine-detecting drone we are developing, we aim to achieve the following objectives:

-

Safe Detection: Using drones to detect mines without human interaction, ensuring the safety of both military personnel and civilians. The only interaction will be remote and secure control by the authorized operator.

-

Speed and Efficiency: Equipped with a Mine Sensor, this drone can swiftly detect mines in large areas, thereby enhancing the duration and effectiveness of military operations and humanitarian aid efforts.

-

Cost Reduction: Providing a solution for detecting and neutralizing mines at a lower cost compared to traditional methods, requiring less manpower and time.

The mine-detecting drone developed within the scope of this project will be a significant step toward creating a safer environment for military personnel and civilians. Its purpose is to safeguard human lives and prevent potential disasters caused by mines.

Scope of Project

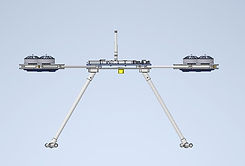

In military operations, mines have been used for various purposes such as slowing down operations, causing material damage to enemy forces, and inflicting casualties. However, due to the lack of a mine detector that provides definite results and the slow and hazardous nature of ground-based scans, the significance of using drones for mine detection has emerged. This study aims to design a modular mine detector compatible with rotary-wing unmanned drones.

Mine detection drone operations will facilitate operations in areas inaccessible to ground forces or where land transportation is difficult, thereby enhancing reliability. This method differs from mine detectors integrated into unmanned ground vehicles; whereas ground vehicles carry the risk of setting off mines, drones conducting scans can avoid this risk, thereby enhancing the secrecy and safety of operations.

In this study, mechanical, software, and computer engineers will collaborate to design a low-cost, high-quality rotary-wing drone suitable for military use. The goal is to rectify the accuracy deficiencies in current mine detection methods and eliminate the security risks associated with ground-based scans. Initially, calculations necessary for the drone to perform various maneuvers like balancing and flying will be executed and then translated into software. Subsequently, the mine detection drone will be lifted from a safe area using remote control and directed to the designated zone to commence mine search operations. This flight will last approximately 12-15 minutes. In addition, depending on the quality of the controller and the drone, the achievable flight time and distance will either increase or decrease. As the quality decreases, the duration and distance decrease, and as it increases, the duration and distance will increase as well. An interface allowing drone operators to operate the drone will be developed, facilitating interaction between the drone and the drone operator.

The drone will fly in a controlled manner within a specified distance which is at least 40 centimeters above the ground, maintaining the necessary proximity for mine detection without compromising the vehicle's safety. Since the pilot cannot ascertain ground contact while operating the vehicle, sensor software is planned for this control. The drone will communicate the detected mine locations to the drone operator with the assistance of the mine detector, utilizing software for this communication.

Product Perspective

Our project of a mine detection aerial vehicle is developed to ensure human safety and detect mines. Initially, the aim is to plan the necessary calculations for the flight capability of the aerial vehicle and software processes ensuring its maneuverability. Subsequently, the intention is to remotely lift the aerial vehicle from a secure area and transport it to the designated zone to commence the mine scanning process. For these procedures, the user interface design will be executed using appropriate interface design software.

While flying over the designated area, the aerial vehicle will maintain a specific distance which is at least 40 centimeters above the ground, close enough to detect mines yet ensuring safety without causing harm to the drone. As the pilot might not be able to gauge the proximity between the drone and the ground, we plan to utilize sensor software to oversee this process. The aerial vehicle will communicate with the mine detector via software to relay the positions of detected mines to the drone operator.

Throughout history, mines have been employed in wars for various purposes like slowing down operations, inflicting material damage, and causing human casualties. However, the absence of a definitive mine detection device and the slow and hazardous nature of ground-based scans emphasize the significance of aerial scanning in this domain. During this era of evolving rotary-wing unmanned aerial vehicle projects, it is anticipated that mine detectors could be integrated into these aerial vehicles.

The objectives of this project encompass the stable flight capability of the rotary-wing aerial vehicle, its resilience against adverse weather conditions, the harmonious functioning of the mine detector with the aerial vehicle, processing acquired data for transfer to a GPS module, and initiating mapping operations. The mine detection application via the aerial vehicle will record the positions of detected mines within the designated area and transmit this information to the control center, enabling communication with relevant units.

Our project of a mine detection aerial vehicle is developed to ensure human safety and detect mines. Initially, the aim is to plan the necessary calculations for the flight capability of the aerial vehicle and software processes ensuring its maneuverability. Subsequently, the intention is to remotely lift the aerial vehicle from a secure area and transport it to the designated zone to commence the mine scanning process. For these procedures, the user interface design will be executed using appropriate interface design software.

While flying over the designated area, the aerial vehicle will maintain a specific distance which is at least 40 centimeters above the ground, close enough to detect mines yet ensuring safety without causing harm to the drone. As the pilot might not be able to gauge the proximity between the drone and the ground, we plan to utilize sensor software to oversee this process. The aerial vehicle will communicate with the mine detector via software to relay the positions of detected mines to the drone operator.

Throughout history, mines have been employed in wars for various purposes like slowing down operations, inflicting material damage, and causing human casualties. However, the absence of a definitive mine detection device and the slow and hazardous nature of ground-based scans emphasize the significance of aerial scanning in this domain. During this era of evolving rotary-wing unmanned aerial vehicle projects, it is anticipated that mine detectors could be integrated into these aerial vehicles.

The objectives of this project encompass the stable flight capability of the rotary-wing aerial vehicle, its resilience against adverse weather conditions, the harmonious functioning of the mine detector with the aerial vehicle, processing acquired data for transfer to a GPS module, and initiating mapping operations. The mine detection application via the aerial vehicle will record the positions of detected mines within the designated area and transmit this information to the control center, enabling communication with relevant units.

Our Project Design

Product List

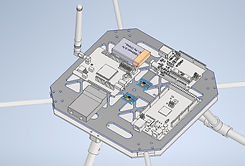

Product Type | Product Name | Product Information | Number of items |

|---|---|---|---|

Carbon Fiber Plate | 50cmx50cm

5mm

Kalınlıkta

Karbon Fiber

Plaka

| https://www.kompozitshop.com/karbonfiber-plaka-pro-t5mm-50cmx50cm | 2 |

Propeller Balancing Tool | Saf Karbon

Fiber

Manyetik

Pervane

Dengeleyici | https://www.dronmarket.com/urun/safkarbon-fiber-manyetik-pervane-dengeleyici | 1 |

Balanced Charger | İMAX | B6AC 80W | 1 |

Power Distribution Board (PDB) | Matek | PDB-XT60 Bec 5V & 12V | 1 |

Camera | 5.8 Ghz 40

Kanal FPV

Drone

Gözlük ve

Kamerası, 40

Kanal 5.8G

Kamera, 3''

Ekran

(FPV58) | https://www.kompent.com/5.8-ghz-40-kanal-fpv-drone-gozluk-ve-kamerasi-40-kanal-5.8g-kamera-3-ekran-1715 | 1 |

Acceleration and GYRO Sensors | MPU 6050 | Weight: 20 Gram | 2 |

Metal Detector Sensor | FLC-100 | Weight: 40 Gram | 1 |

Flight Control Card | Arduino

Mega | Weight: 40 Gram | 1 |

Battery for GPS | 3.7V 1S

1300mAh

1cell LiPolymer Pil 40C -

PX1300XP

| 1S 1300 Mah Li-Po Pil | 1 |

GPS Module Card | Arduino Uno

(Klon) | Weight: 40 Gram | 1 |

Controller | FLYSKY FSİ6X

| 10 Kanal, 2.4Ghz, 26mm Çift Anten, 500-1500

metre menzil | 1 |

Proximity Sensor | HC-SR04 | Ölçüm Aralığı: 2cm-400cm, Verimli Ölçüm

Aralığı: 2cm-200cm, Ağırlık: 10 Gram | 6 |

GPS Module | Kapadokya

GSM Shield | GSM kullanarak yüksek konum doğruluğu

sağlar.

https://www.robolinkmarket.com/kapadokyagsm-shield-arduino-gsm-shield | 1 |

Propeller | T-MOTOR

NS17X5.8 CF

(Ultra Light)

PROP. | 17x5.8 Carbon Fiber(Ultra Light), Weight: 16.5

Gram

| 4 |

Brushless Motor | T-MOTOR

MN5008

Antigravity

Type 6-12S

UAV

Motor340KV

IP35

| 340 KV, Weight: 135 Gram | 4 |

Electronic Speed Control | AIR 40A 2-

6S MultiRotor UAV

Drone

airplane ESC | 6S,40 Amper,Weight: 26 Gram | 4 |

Battery | Leopard

Power 6200

mAh 22.2V

6S 30C Lipo

Batarya Pil T

Plug | 6200Mah, 22.2V, 30C, 6S, Weight: 888 Gram | 1 |